A New Approach to Virtual and Physical Testing Gives New Insights on How to Protect the Brain from Concussions

A New Approach to Virtual and Physical Testing Gives New Insights on How to Protect the Brain from Concussions

ANAHEIM, Calif.--(BUSINESS WIRE)-- National Technical Systems, Inc. (“NTS”), the leading independent provider of qualification testing, inspection, and certification solutions in North America, is pleased to announce its partnership with AES R&D to conduct virtual and physical testing of the revolutionary anti-rotational kinematics (ARK) helmet.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20191121005298/en/

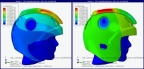

Virtual Simulations Highlight Areas of Stress (Graphic: Business Wire)

ARK helmet technology is the creation of Maryland-based AES R&D, a company that researches and designs innovative and more effective head-protection systems. ARK helmets are designed to prevent the head and helmet from spinning during impact, which strains the brain. ARK technology allows the outer shell of the helmet to move upon impact to eliminate part of that energy. With a glancing blow to the helmet, for example, the inner shell remains stationary, thus limiting skull and brain movement during a collision.

The partnership allows NTS to test the impact in the laboratory and run virtual simulations using AES R&D’s Biofidelic brain and head model, which was created by John Hopkins University. NTS is uniquely positioned to assess data from both virtual and physical spaces to objectively assess impact with greater precision.

John Hopkins University Develops Virtual Brain Model to Test New ARK Football Helmet

As AES R&D researched the design of the ARK football helmet, it found that over half of the concussions in football occur due to glancing blows, which cause rotational forces and accelerations. As a result, AES utilized a new virtual biofidelic brain and head model created by scientists at John Hopkins University. AES used this pioneering technology to develop the ARK concept through simulation guided design, specifically by running tests in the virtual world prior to building a physical prototype. The result was that AES developed a new standard of helmet more quickly and with greater accuracy at a lower cost, through virtual simulations using the Hopkins model.

Testing Virtual Simulation Technology

NTS is the only testing laboratory capable of translating AES’s ground breaking virtual simulation technology to a physical testing situation. NTS digitally reproduced its physical testing simulations; quickly measuring acceleration, linear, and angular impact rates on the brain. One test revealed a 38% reduction in strain to the brain under the protection of the ARK helmet.

“We believe ARK technology is the breakthrough helmet manufacturers have been looking for in designing and producing advanced protection for athletes, military personnel, law enforcement and other applications,” said NTS CEO Rich Adams. “By running tests in the virtual world—and then translating those tests into physical testing in the laboratory—NTS engineers are able to provide the most complete and thorough assessment of helmet technology in the marketplace today,” Adams continued.

The nimble method of testing means the AES team can make design adjustments digitally, instead of physically reproducing designs after each test.

ARK Technology Available to Helmet Manufacturers Worldwide

Starting in 2020, through NTS, AES R&D will be making its virtual biofidelic brain model available to helmet brands and manufacturers industrywide. The aim is to collaborate with clients in developing new levels of safety in head protection and to help those clients reach their goals more quickly at a greatly reduced cost. “Our goal is for the ARK logo to become the recognized standard for safety in helmets” said Steve Arzoni, VP, AES R&D. “When you see the ARK logo on any helmet - sports, law enforcement, or military - you know you’re going to be safer.”

About National Technical Systems

National Technical Systems, Inc. (“NTS”) is the leading provider of qualification testing, inspection, and certification services in North America, serving a broad range of industries, including civil aviation, space, defense, nuclear, telecommunications, automotive, industrial, electronics, and medical end markets. Since 1961, NTS has built the most extensive geographic presence in the United States, offering more than 70 distinct product qualification and materials testing categories, including climatic, structural, dynamics, fluid flow, EMI/EMC, lightning, product safety, acoustics, failure analysis, chemical, and other industry-specific tests. Operating through a network of 28 technologically advanced testing laboratories, this geographically diverse footprint puts NTS facilities in proximity to its more than 8,000 clients—allowing NTS to serve the nation’s most innovative companies with unmatched accessibility and responsiveness. NTS is accredited by numerous national and international organizations and operates its inspection division under the Unitek brand, providing a wide range of supply chain management services. NTS’ certification division, which operates under the NQA brand, is one of the largest and most respected global ISO registrars, with active certifications in more than 75 countries. For more information about NTS, visit www.nts.com or call 800-270-2516.

About AES R&D

AES R&D is the one-stop shop for research and design solutions for advanced head protection systems. Leaders in virtual simulation guided design. Core Competences include Break Frame Innovation, Computational 3D Modeling, Rapid Prototyping, Design and Engineering Services and Solution Development. For fun information on AES R&D visit www.AESRandD.com, call 443-660-6080 or e-mail Steve@AESRandD.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20191121005298/en/

Contacts

Sarah Willis, Vice President of Marketing

714-450-9100

sarah.willis@nts.com

Source: National Technical Systems, Inc.

Smart Multimedia Gallery

View this news release and multimedia online at:

http://www.businesswire.com/news/home/20191121005298/en